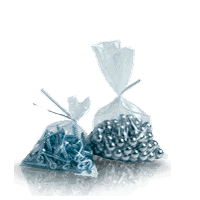

POLY BAGS

Explore the versatility of our Poly Bags, designed from LDPE or LLDPE for cost-effective packaging solutions. Ideal for storage, shipping, and product protection, our experts can guide you in selecting the perfect size and thickness to meet your specific requirements.

Flat Poly Bags

Benefits of Poly Bags

Poly bags provide numerous advantages over other packaging options, including:

- Durability: Strong and long-lasting, poly bags offer excellent protection for products during shipping and storage.

- Water Resistance: These bags are resistant to moisture, making them ideal for items that need to stay dry.

- Transparency: Many poly bags are clear, allowing customers to easily view the contents inside without needing to open the package.

- Cost-Effectiveness: Poly bags are a budget-friendly packaging option, providing high performance at a low price.

Applications for Poly Bags

Poly bags are versatile and used across a range of industries, including:

- Food and Beverage: Perfect for packaging items like bread, produce, snacks, and other perishable goods.

- Retail: Commonly used for packaging apparel, electronics, toys, and other retail products.

- Industrial: Ideal for hardware, machine parts, medical supplies, and other industrial goods.

Material Specifications

-

Types of Polyethylene:

- LDPE (Low-Density Polyethylene): Offers flexibility and softness, suitable for lightweight packaging. It’s commonly used in food packaging due to its moisture resistance.

- HDPE (High-Density Polyethylene): More rigid and durable, perfect for industrial applications that require puncture resistance.

- Linear LDPE: Combines strength with flexibility, ideal for heavy-duty uses.

-

Thickness & Durability:

- Poly bags come in various thicknesses, measured in mils:

- 1-2 mils: Suitable for lightweight items like clothing.

- 3-4 mils: For medium-duty uses such as retail packaging.

- 6+ mils: Best for heavy-duty, industrial items like machine parts.

- Thicker bags offer higher puncture and tear resistance, making them ideal for protecting heavier or more fragile products.

- Poly bags come in various thicknesses, measured in mils:

-

FDA Compliance:

- Poly bags intended for food contact must meet FDA standards, ensuring they are made from virgin resins to avoid contamination.

-

Chemical and Environmental Resistance:

- These bags resist chemicals, moisture, and dust, making them perfect for packaging sensitive products like electronics, pharmaceuticals, and industrial materials.

-

Sustainability:

- Offer biodegradable or recyclable poly bag options for eco-conscious customers. Mention your commitment to reducing environmental impact by providing green alternatives.